In the realm of light industry, few elements typify the challenge of weak alkaline environments (pH 8) like there is none. Chemicals and reagents of this nature are common in factories and laboratories, but they pose a daunting challenge to traditional materials.

A classic example of this challenge is the bellows coupling, traditionally a metal component. However, in a weak alkaline environment, metal components undergo passivation, leading to leaks and corrosion. This is a problem that no engineer would wish to encounter.

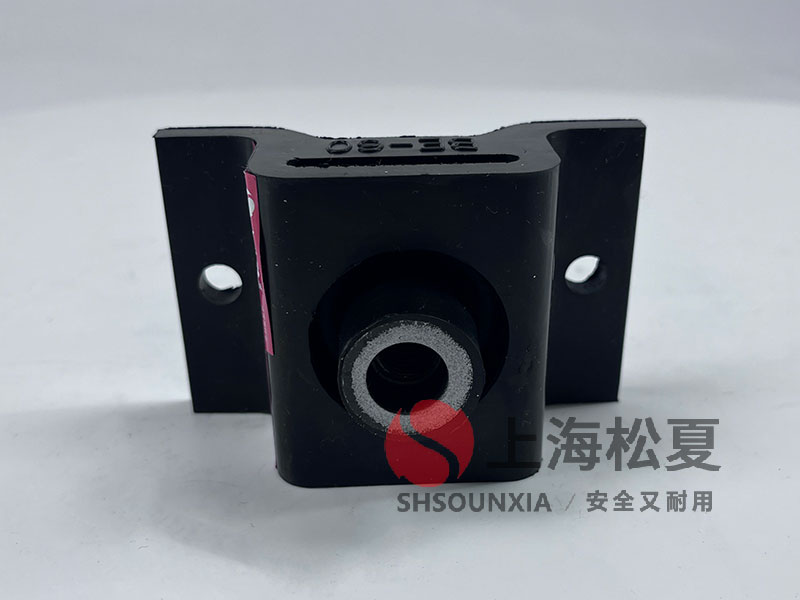

Rubber couplings, on the other, have emerged as a viable solution. Rubber, a material resistant to corrosion, is perfectly suited to this environment. It maintains seals and prevents leaks, all the while being safe for the environment and user.

The rubber bellows coupling is designed to withstand the demands of weak alkaline environments. Its flexibility allows it to bend and conform to the shape of the pipe, while its seal ensures a watertight connection.

In industries as diverse as chemicals, pharmaceuticals, and oil and gas, this coupling is proving indispensable. It is a testament to the ingenuity of materials science.

Shanghai Xinxia Dampening Products Co., Ltd. is at the forefront of this innovation. A trusted name in the industry, they continue to refine and develop rubber bellows couplings. Their products are not only durable but also engineered to meet the needs of the most demanding applications.

This is but one of the many examples of how tailored solutions can transform industry. By understanding the challenges of your environment, and tailoring your materials to meet them, you can achieve results that are not only efficient but also reliable.