In the fast-paced world of industrial operations, the reliability of equipment under extreme conditions is paramount. For applications involving high-pressure systems, such as fire fighting, chemical plants, and water treatment facilities, the choice of coupling can make or break performance. Enter the versatile and durable flanged rubber coupling (also known as a pressure coupling or expansion coupling), specifically designed for use with high-pressure pumps.

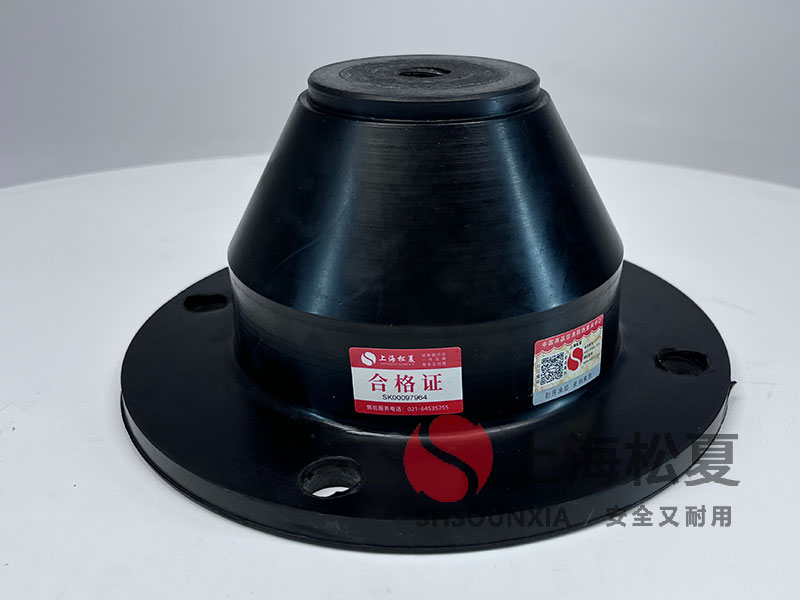

A flanged rubber coupling is a flexible rubber intermediary that connects two mechanical components, ensuring reliable operation under pressure. These couplings are commonly used in industrial settings where components are subject to fluctuating pressure, shocks, and vibrations. Unlike metal couplings, which can degrade under harsh conditions, rubber couplings offer a robust solution for high-pressure environments.

Durable and Reliable Performance: Flanged rubber couplings are built to withstand high pressures and temperatures. They are ideal for applications where components are exposed to extreme conditions, such as fire hydrants and chemical plants.

Resistant to Environmental Factors: These couplings are weatherproof and can operate in both dry and wet conditions, making them suitable for a wide range of industrial environments.

Vibration Dampening: The flexible nature of rubber couplings helps reduce noise and vibration, ensuring smooth operation of pumps and other machinery.

Sealed Design: Many rubber couplings feature built-in O-rings or gaskets, ensuring a watertight seal and preventing the ingress of liquids and particulate matter.

Cost-Effective: While flanged rubber couplings may have a higher initial cost than metal couplings, they offer long-term savings by reducing the risk of component failure and downtime.

Ensure Proper Alignment: Before installing a flanged rubber coupling, ensure that the pipes being connected are properly aligned. Misalignment can lead to vibrations and poor performance.

Follow Manufacturer Guidelines: Each coupling has specific size and pressure ratings. Always follow the manufacturer's guidelines to ensure compatibility and safety.

Regular Inspection: Periodically inspect the coupling for signs of wear or damage. Tightening the flange can help prevent loosening over time.

Sealing: Ensure that the coupling is installed in a way that allows for proper sealing. Proper sealing prevents leaks and extends the life of the coupling.

Environmental Considerations: Flanged rubber couplings are ideal for use in environments with wet or aggressive liquids, such as those found in fire hydrants and certain industrial processes.

In conclusion, flanged rubber couplings are an essential component for maintaining reliable performance in high-pressure systems. By choosing the right type of coupling and following best practices for installation and maintenance, you can ensure that your equipment operates efficiently and safely, even under the most demanding conditions.